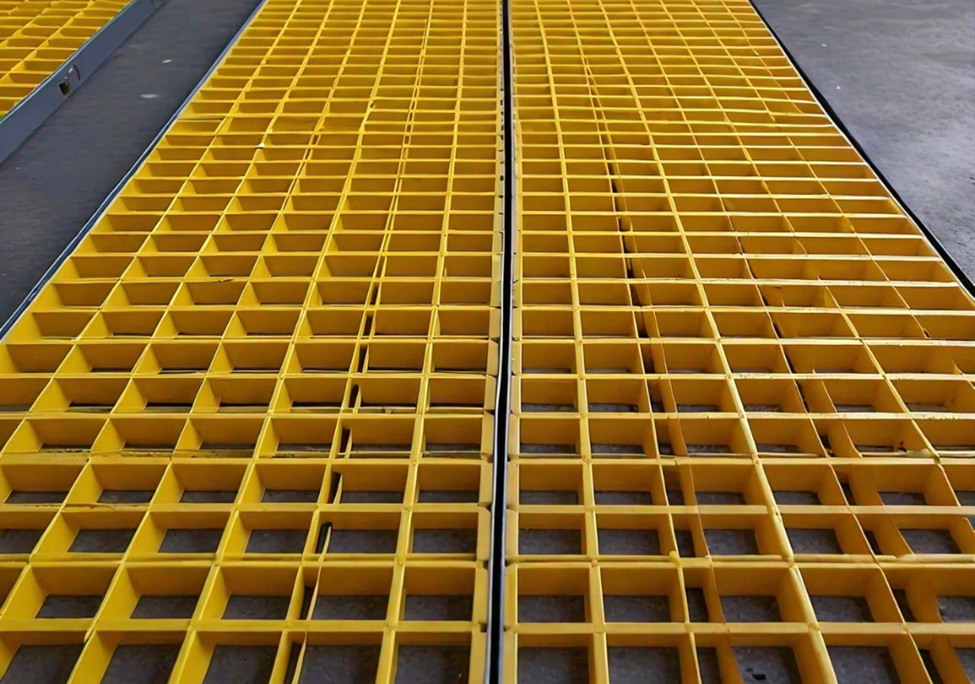

FRP (Fiber-Reinforced Polymer) grating is a type of grating made from a composite material consisting of fiberglass roving’s and mats embedded in a polymer resin. It is a popular alternative to traditional metal grating due to its corrosion-resistant properties, durability, and low maintenance requirements.

FRP grating is manufactured using various processes, including:

FRP grating offers several benefits, including:

FRP grating is commonly used in various applications, including:

FRP grating comes in various types, including:

When selecting FRP grating, consider factors such as:

| RESIN TYPE | GRATING TYPE | DESCRIPTION | APPLICATION |

|---|---|---|---|

| Vinyl Ester | Type VE | Superior corrosion resistance | Environment with high corrosion problems. |

| Flame resistant Vinyl Ester | Type VE-FR | Superior corrosion & Flame resistance | Environment with high corrosion requiring better flame resistance. |

| Isophthalic Polyester | Type IP | Industrial grade corrosion resistance | Used in the environments of normal or less concentration inorganic acid, alkali, etc. |

| Flame resistant Isophthalic polyester | Type IP-FR | Industrial grade corrosion & Flame resistance | Used in less concentrated inorganic acidic areas requiring better flame resistance. |

| Orthophthalic polyester | Type OP | Moderate grade corrosion resistance | For use in environment which requires water & weather proof solution. |

Driving success to your business

Makewell Composite is driving success in various industries with its innovative FRP solutions. By providing lightweight and corrosion-resistant FRP products, the company is boosting efficiency and reducing costs for its customers. With expert design and manufacturing capabilities, Makewell Composite is empowering industries to achieve exceptional performance and sustainability. As a trusted partner, Makewell Composite is committed to delivering high-quality FRP products and exceptional customer experience, ultimately driving business success.